- DX vision

- DX strategy

- DX organization

- Development of human resources for digital

- DX initiative references

- Cloud data platform

DX vision

Our business has long benefited from the widespread use of digital technology in the Oil and gas industry. In recent years, cutting-edge digital technology has made data processing faster and more sophisticated, enabling us to utilize large volumes of diverse data. INPEX is actively working to transform the energy landscape to help achieve a net-zero carbon society by 2050, while meeting the energy demands of Japan and the world. The use of digital technology is positioned as an important pillar of these efforts.

In INPEX Vision 2035, we aim to improve productivity through the use of digital technology, thereby contributing to the enhancement of corporate value.

In line with this vision, we define the role of DX in our company as promoting internal innovation in organizations, employees, culture and mindset through digital, and leading the advancement of operations to address changes in the external environment. By utilizing advanced digital technology to establish sophisticated business processes and create new value, we aim to build competitive advantages.

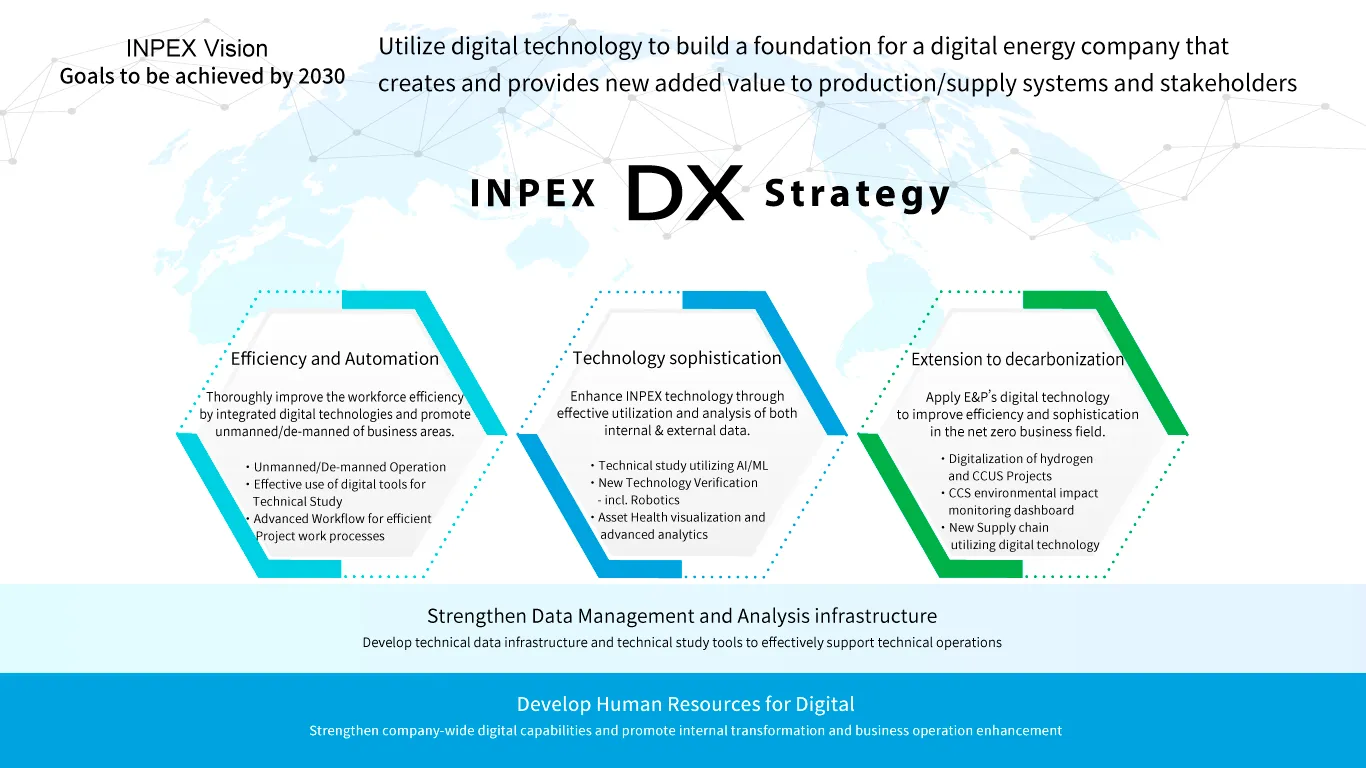

DX strategy

Our DX strategy aims to promote the resilience and sustainability of our oil and natural gas business by digitalizing operations in accordance with our medium-term business plan and Technical strategies. Furthermore, as part of our ongoing efforts to improve our operational structure, we have formulated a plan to increase efficiency and create new value by establishing a digital data infrastructure and accelerating the adoption of digital technology. The DX strategy focuses on the following five items.

-

1.Efficiency & automation: Thorough improvement of workforce efficiency using integrated digital technologies and promoting unmanned/de-manned business areas.

-

2.Technology sophistication: Enhance INPEX technology through effective utilization and analysis of both internal and external technical data.

-

3.Extension to decarbonization: Application of E&P's digital technology to improve efficiency and sophistication in decarbonization fields (e.g. CCUS, hydrogen/ammonia, renewable energy, methanation).

-

4.Strengthen data management/analysis and infrastructure: The development of technical data infrastructure and technical study tools to effectively support technical operations.

-

5.Development of human resources for digital: Strengthening company-wide digital capabilities and promoting internal transformation and business operation enhancement.

DX organization

To bolster initiatives related to digital transformation (DX), the DX Group of the Technical Division will implement digital measures based on specific challenges. In collaboration with business departments and domestic and overseas bases, we will plan and propose specific digital measures from a data-based, holistic and optimal viewpoint for the specific challenges that each worksite faces. Furthermore, we will promote knowledge sharing and collaboration for problem-solving between departments and worksites.

Individual digital projects are consistently promoted from the proof of concept (PoC) stage to full-scale implementation by project teams or task forces composed of members of the DX Group and business departments. For important projects, a steering committee comprised of several department directors is established to make judgments and provide support from a management perspective.

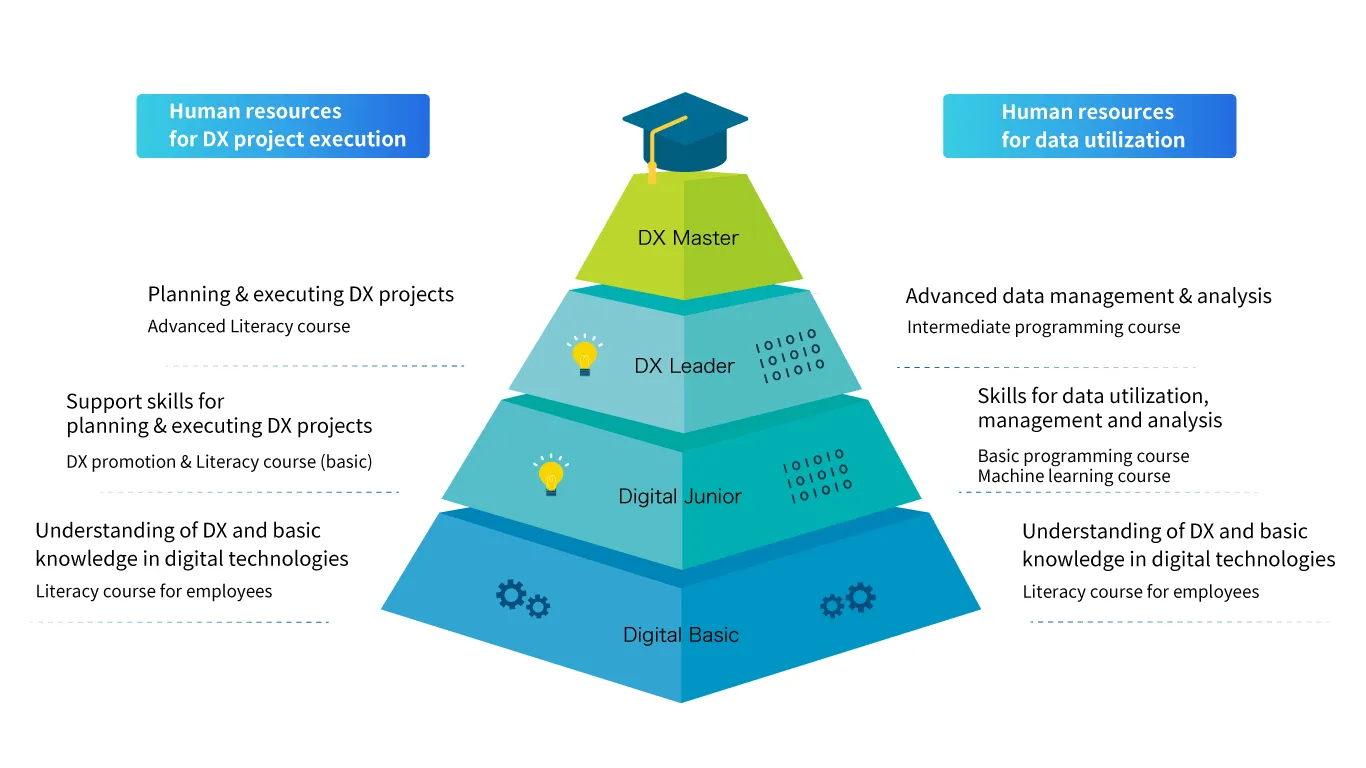

Development of human resources for digital

Developing human resources for digital is one of the crucial initiatives under the DX Vision. By identifying the required knowledge and skills and conducting practical training programs, we aim to develop digital human resources that can create new business value and customer experiences.

INPEX has defined the prerequisite of two skill categories and separately implements training programs for basic and advanced levels.

-

1.Human resources for the planning and execution of DX projects.

-

2.Human resources for data utilization, management and analysis.

To enhance the digital literacy of employees, we provide basic programming courses and post a variety of DX information on our groupwide portal. In addition, we offer data science course to develop special skillsets. We intend to continue conducting training courses focused on digital literacy, programming and data science throughout the company.

DX initiative references

-

Unmanned/de-manned and robots

-

Central Processing Facility (CPF) digital visualization project

-

Digitization of work permit application (Permit Plus)

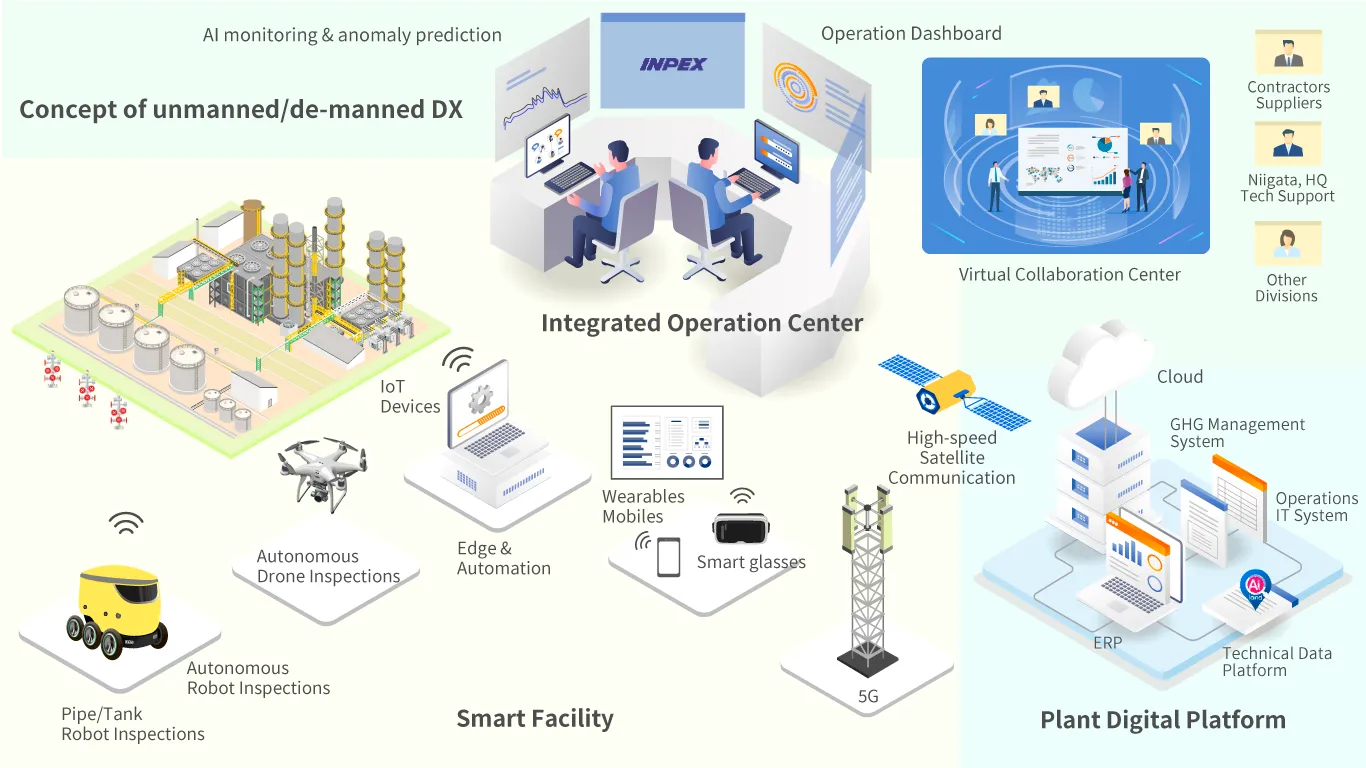

Unmanned/de-manned and robots

With the aim of ensuring safety and maintaining/improving the competitiveness of production and operations, we are working toward comprehensively implementing the integrated DX measures at existing production facilities. Based on the following three concepts, we have been executing a small-scale pilot project since spring 2022 with a view to conduct full-scale deployment.

Concept

- Integrated operation center:

- Integrated control and monitoring of multiple facilities assisted by AI monitoring, collaboration center, etc.

- Smart facilities:

- Improving the automation level of field work, various sensing technologies, and data transfer with integrated operation center.

- Plant Digital Platform:

- Seamless integration among multiple system platforms supporting the operation processes

Following reviews and verifications conducted since 2022, we are enhancing the functions of the Integrated Operations Center as we look towards 2025. Specifically, we have begun deploying a remote/integrated monitoring system that spans multiple plants in actual operations.

Furthermore, we are advancing the following initiatives as part of the sophistication of operation management:

-

Efficient routine inspections utilizing explosion-proof digital devices.

-

Automation of operation records that coordinate with routine inspections and a wireless sensor and plant data management system.

Through the introduction of these digital technologies, we are realizing improvements in business processes and operation efficiency.

In addition, we are progressing with demonstrative verification of production facility inspections using robotic technology, aiming for efficient inspection of infrastructure facilities. Further, we are undertaking the implementation verification of equipment monitoring systems using IoT cameras with AI functions. These actions are all steps towards realizing early detection of anomalies and efficient routine inspections.

Central Processing Facility (CPF) digital visualization project

We are deploying a visualization project using the digital twin of the Central Processing Facility (CPF) at the Ichthys LNG Project in Australia. Utilizing drones, advanced LIDAR, and photogrammetry scanning technologies, we are innovatively improving the planning, execution, and management methods of the facilities. This initiative is achieving enhancements in safety, improvements in work efficiency, and support for offshore work planning. Traditionally, engineers and planners needed to make repeated site visits for setting work scopes and verification since access to remote facilities was limited. However, with this tool, walkthroughs in the virtual space of the facility are possible, realizing improvements in the quality of work planning, strengthening safety, and significantly reducing the required time at offshore facilities.

Digitization of work permit application (Permit Plus)

At the Ichthys LNG Project in Australia, we have developed the application "Permit Plus," which digitizes the authorization and management of hazardous work on-site, transforming field operations. This application, jointly developed by the Operations and Technology departments, streamlines the work permit process, improving productivity and efficiency. It is based on field operating-centered design, user-friendly intuitiveness, robust infrastructure, and compliance with governance, providing workers with effective and highly safe tools. The main advantages of this application include reducing transit time and downtime due to direct on-site work permit management, improving productivity due to seamless transition from meetings to tasks, and enhancing work permit tracking and compliance with safety protocols due to real-time updates.

Cloud data platform

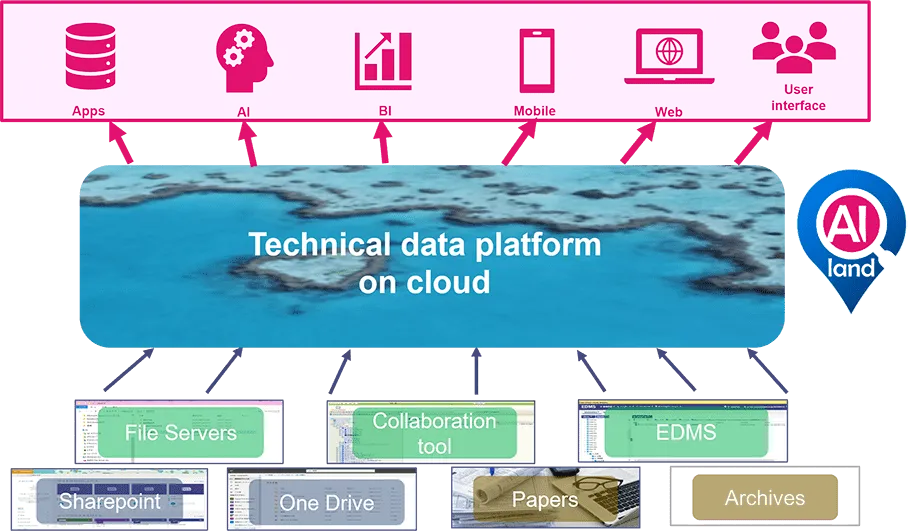

Technical data Infrastructure AI-land for exploration and development data management

The technical data infrastructure "AI-land" has been in operation since 2021 as a system for managing technical data on the INPEX cloud. This infrastructure is a cloud storage that securely keeps seismic exploration data and well data indispensable for underground evaluation and a geographic information system (GIS). By 2024, we plan to expand the subject to past underground evaluations, promoting knowledge sharing, and conduct introduction tests for data science functions to highly utilize the accumulated information and knowledge, progressing towards full implementation from 2025. By doing so, we are developing information infrastructure that organizationally utilizes accumulated knowledge, contributing towards our transformation into a new energy company.

Society's views toward a net-zero carbon society have posed new issues limiting the expansion of business avenues of Oil and gas companies, but conversely, they have also created new business opportunities. One example is the visualization of geospatial data by overlaying the maps of well and seismic exploration data in AI-land utilizing maps of CCS and CO2 emission sources data. Such initiatives contribute toward new synergistic approaches for realizing a net-zero carbon society.

Strengthening of data governance has been the critical challenge for constructing the solid infrastructures of digital platforms. As such, the data management procedures must be improved to prevent data management on an individual basis. The definition of the principles of technical data management and processes along with performing centralized data management under the company-wide rules have contributed toward realizing a high level of security and accessibility as well as maintaining data quality.

Furthermore, AI-land has contributed to the implementation of remote-working system that has become prevalent since 2020 by offering a safe and simple method for employees to access technical data from their homes and utilizing cloud technologies.