CO2EOR

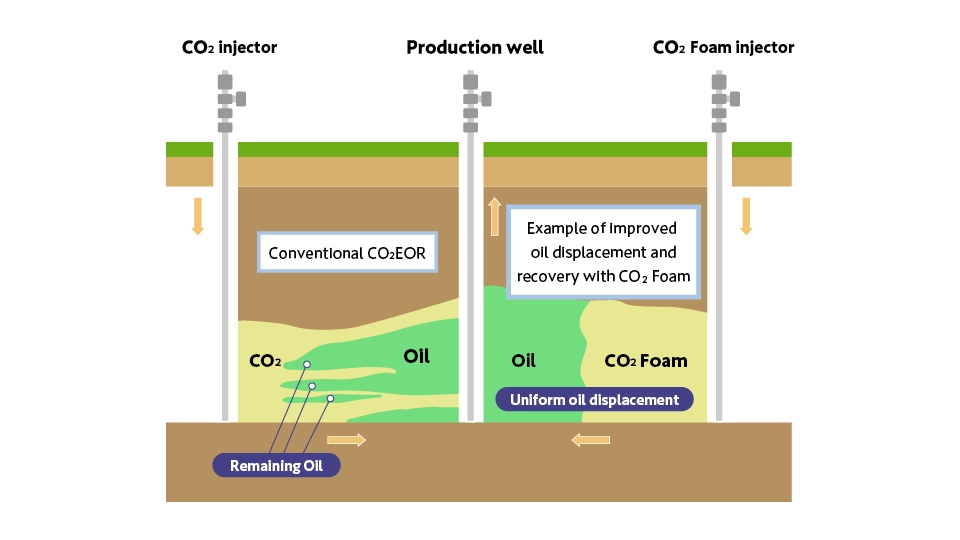

Injecting carbon dioxide (CO2) into oil reservoirs is a noteworthy Enhanced Oil Recovery (EOR) technique that can contribute to reducing greenhouse gas emissions by storing CO2 underground while also increasing oil recovery.

However, CO2 is both lighter and less viscous than oil, which can result in it infiltrating only the high permeability layers, leaving a significant amount of oil unrecovered in the reservoir. To overcome this issue, we are developing specialized techniques to ensure more efficient oil recovery. These include fluid mobility control techniques by mixing CO2 and water to form a foam, or blending CO2 and a thickening agent to increase viscosity.

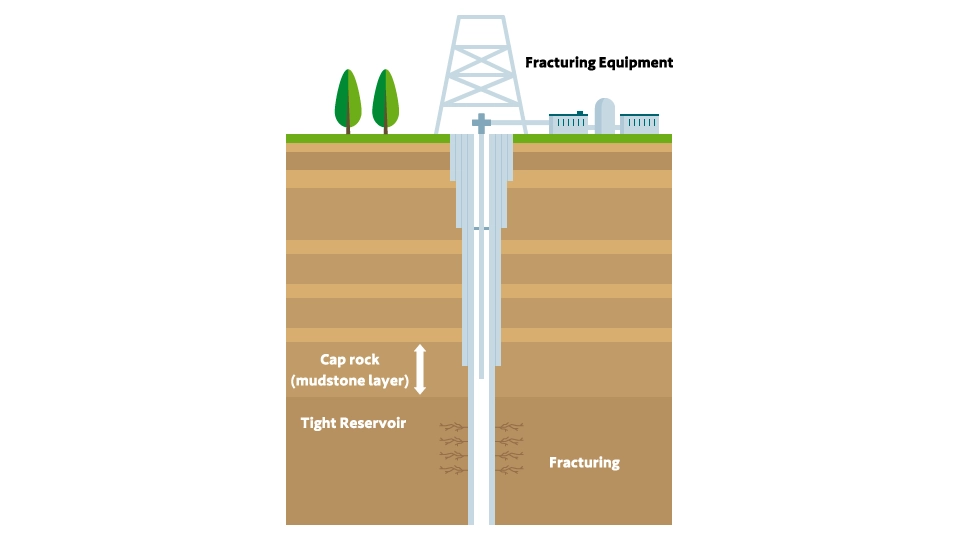

Fracturing technologies

Generally, when a reservoir has low permeability, there can be challenges in ensuring sufficient production or injection rates during Oil and gas production or water and CO2 injection. Through domestic and international Oil and gas field development, our company has cultivated fracturing technology, essential for the development of tight reservoirs. We aim to further advance this technology and realize demonstration projects in our existing gas fields using advanced completion techniques such as CO2 fracturing and thermal fracturing.

Reservoir simulation technology

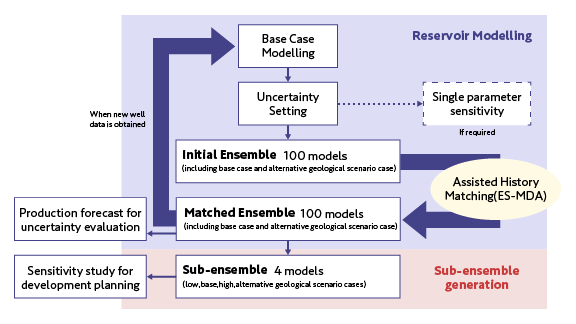

By modeling underground reservoirs and simulating fluid (oil, gas, water) flow within them, it is possible to create more economical development plans, including the number and locations of wells. However, the underground reservoir is invisible, and there's uncertainty in the reservoir interpretation, such as depth and permeability distribution of the reservoir. Thus, the pre-drill predictions can deviate significantly from the actual results. Therefore, it is necessary to construct multiple geological scenarios for the reservoir modeling, evaluate uncertainties in varied reservoir parameters, and derive development plans inclusive of risk mitigation measures.

Our company is working on developing a workflow for efficient uncertainty evaluations and formulating development plans accordingly. As numerous models need to be created for the evaluation, manual history matching - the process of adjusting the reservoir model to fit the field data - is not an easy task. Therefore, we have combined an automatic history matching technique to the workflow, resulting in a significant reduction in work hours. Through such efforts, we aim to improve our understanding and accuracy of reservoir risks and implement effective risk management in Oil and gas field development.

-

Uncertainty Evaluation Workflow Utilizing Automatic History Matching

-

Reservoir simulation diagram

References

Narumi R., Iizuka R., Miyazaki T. et al., Demonstration of a Practical Ensemble-Based Reservoir Modelling Workflow for Development Planning on the Ichthys Gas-Condensate Field