What are oil and natural gas?

What is oil?

Oil is a liquid mineral resource, composed mainly of compounds (hydrocarbons) of

carbon and hydrogen.

There are various theories about the formation of petroleum, but the following

explanation is widely adopted in current oil and natural gas development

circles. In ancient times, the remains of plankton in the water were deposited

in shallow seas or lakes along with sediment, and during the process of being

buried under layers of mud and sand, they were transformed into an organic

matter called kerogen. Chemical reactions progressed, and subject to the earth’s

heat, the kerogen decomposed over time into a liquid form that is crude oil as

well as a gaseous form that is natural gas.

Today, oil is used as transportation fuel such as gasoline, diesel fuel, jet

fuel, heavy oil, and as fuel for power generation as well as a raw material for

rubber products such as tires, plastic products such as PET bottles, chemical

fibers used in clothing, detergents and shampoos. Our lives are supported by

oil, across various aspects of daily life.

What is natural gas?

Like oil, natural gas is also a hydrocarbon, but it is said to have less impact on

the environment compared to oil. Natural gas, with methane as its main component,

contains almost no impurities, including harmful carbon monoxide. Therefore, when

combusted, the amount of nitrogen oxides and carbon dioxide produced is less than

that of coal and oil, and it does not generate sulfur oxides, which is a distinctive

feature.

Natural gas production sites are widely distributed around the world, and reserves

are abundant. Therefore, it is widely believed that the use of natural gas will

further advance in the future due to its long-term stable supply and low

environmental impact.

Natural gas is used as fuel for power generation and as a raw material for city gas,

and it is also garnering attention as a raw material to produce hydrogen, which is

widely viewed as a next-generation energy source. Thus, its range of applications is

expected to expand even further in the future.

Oil and natural gas: from exploration to delivery

Exploration

We locate underground oil and natural gas using the latest information and technology.

1 Analyzing the strata [geological survey]

Even if underground strata are not directly visible, extensions may be exposed above the surface. In a geological survey, such strata are studied and analyzed to determine where the rocks that formed the oil and natural gas are distributed, and where the oil and natural gas may be accumulated.

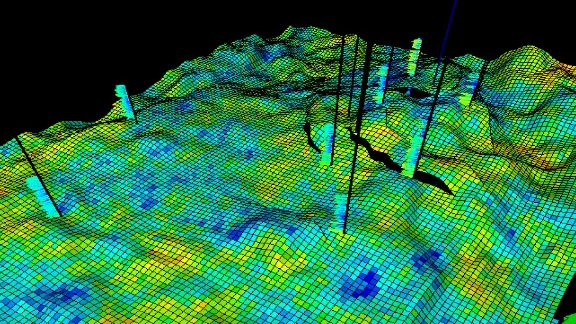

2 Seismic exploration [physical exploration]

Using the physical properties of the rocks that compose the strata, such as hardness and density, the geological structure underground is analyzed. This is called physical exploration. An example of this is seismic exploration, which involves sending artificial sound waves (seismic waves) from the surface into the ground. The seismic waves that return to the surface after hitting underground rocks are analyzed to study the subsurface geological structures.

3 Exploratory drilling [drilling of exploratory wells]

Even in areas that are considered promising as a result of various surveys, the only way to determine the existence of oil or natural gas is to drill a well and analyze the underground conditions. Detailed plans are laid out, such as where and how deep to drill the well, and exploratory wells are drilled.

4 Appraisal and analysis [Production Test]

Even if a layer containing oil or natural gas is discovered through an exploratory well, it is not known if the layer contains a commercially viable quantity. Therefore, a production test is conducted, where oil and natural gas are produced on a trial basis. After a thorough consideration from all aspects, it is decided whether a project should proceed towards full-scale development and production.

Drilling

Wells are drilled to search for and extract oil and natural gas.

1 Setting up a drilling rig [rig installation]

Wells are drilled deep underground to produce oil and natural gas. In preparation for a drilling operation, an iron tower called a derrick, which handles drill pipes, is installed along with various other machinery and equipment. Collectively, these are referred to as a drilling rig.

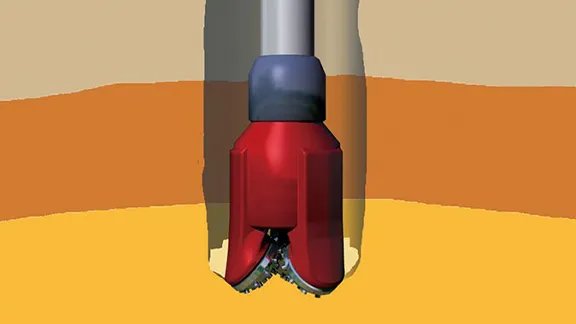

2 Drilling with a bit [Drilling bit]

Wells are drilled from the rig, using drill pipes that are each about 10 meters long. A cutting tool called a drill bit is attached to the end of the pipe, and by utilizing the rotation of the bit and the weight of the pipe, solid rock is penetrated, and the pipe drills towards the target depth. There are various types of bits, and the appropriate one is selected according to the type of rock.

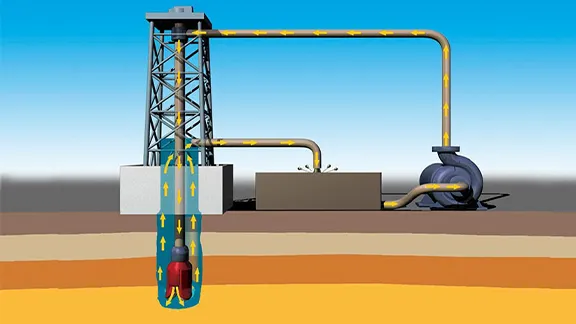

3 Carrying debris with drilling mud [Mud circulation]

Debris including soil and rock fragments that are formed during drilling are removed by pumping viscous fluid called drilling mud from the surface through a powerful pump, ejected from the bottom of the bit, and carried up to the surface. The drilling mud is also used to cool the bit and pipes and to reinforce the formation being drilled.

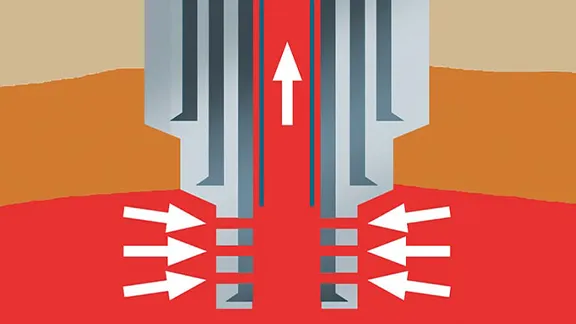

4 Setting casings to support the integrity of the well [Casing]

Iron pipes called casings are set inside the drilled well, as the raw sides of the well would collapse in without support. These casings are lowered in sequence, from bigger to smaller, according to the size of the well in each section and secured with cement slurry between the drilled formation. Once the well is complete, we punch a hole in the casing at the desired depth and produce oil and natural gas.

Evaluation

If Oil and gas are discovered in an exploratory well, characteristics and spread are determined, and a development plan is formulated.

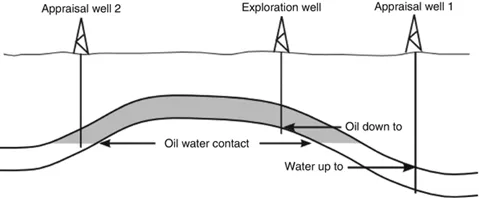

1 Digging around and determining [Drilling of appraisal wells]

When oil and natural gas are found in an exploratory well, it is important to confirm how far they spread. Therefore, appraisal wells are drilled around the exploratory well to further analyze the extent, thickness and characteristics of Oil and gas layers.

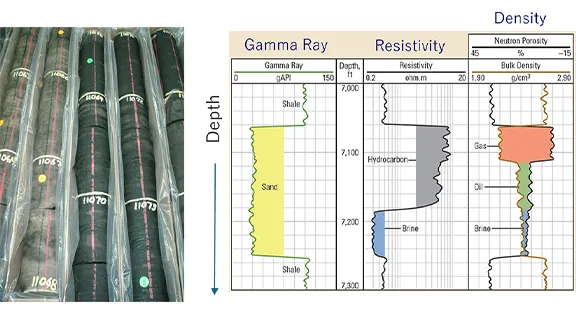

2 Detailed understanding of underground conditions [Acquisition of various data]

From appraisal and exploration wells, samples of rock cores, physical properties such as gamma rays, specific resistance, density, fluid samples such as Oil and gas, as well as well pressure and temperature data can be obtained. By taking advantage of these data comprehensively, the underground structure and characteristics of the storage layer can be understood more accurately.

3 Data is analyzed comprehensively [Evaluation of the reservoir]

Using the data obtained, the extent, nature, pressure, temperature and composition of crude Oil and gas of the storage layer are analyzed in detail. Here, it is judged whether the recoverable reserves (Oil and gas quantity) expected are sufficiently large, and the economic feasibility and possibility of commercialization of the project are examined.

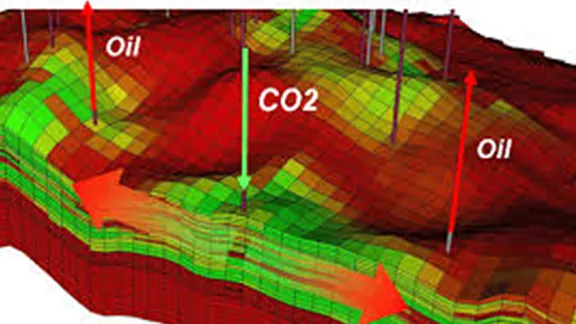

4 Planning for development [Formulation of a development plan]

If reserves that seem economically viable can be confirmed in the assessment work, a development plan is put together aiming for commercialization. The arrangement and number of wells, drilling methods (horizontal wells, fracking technology, etc.), production methods (pressure maintenance by injection of water or gas) are considered, along with the design and selection of production processing facilities and transportation facilities. The goal is to formulate an optimal development plan that maximizes efficiency in extracting Oil and gas and enhances economic viability.

-

CO2 Injection

-

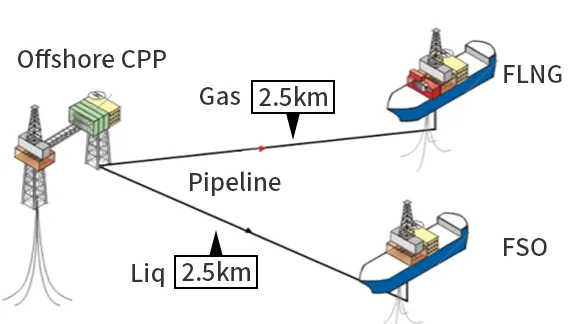

Production Processing Facilities and Transportation Facilities

Development

The development process of creating oil and natural gas facilities proceeds through the following stages:

1 Determining feasibility

[FS: Feasibility Study]

First, consider whether the discovered Oil and gas resources can be established as a business. Market research, rough cost estimations, and risk assessments are carried out to determine the extent of technical and economic possibilities.

2 Choosing the optimal development plan

[CS: Concept Selection]

Multiple development options (such as facility design and production methods) and reserve scale are compared from technical, economic, and environmental perspectives, and the most profitable and effective method is selected. The general direction and method of development become clear at this stage.

3 Proceeding with detailed design

[FEED: Front End Engineering Design]

Based on the selected development concept, more specific designs and plans are carried out. The structure and facilities of the installation, construction schedule, cost, etc., are estimated in detail, and the feasibility of the project is further examined. If the validity of the development is confirmed, we prepare materials for judgment towards the final investment decision (FID).

4 Executing design, procurement, and construction

[EPC: Engineering, Procurement, and Construction]

Once the project's execution is determined by the final investment decision (FID), a more detailed design is implemented, and the procurement of necessary materials and equipment and onsite construction work are performed. Through trial runs and startups, the facility is launched into a state where actual oil and natural gas can be produced.

Production

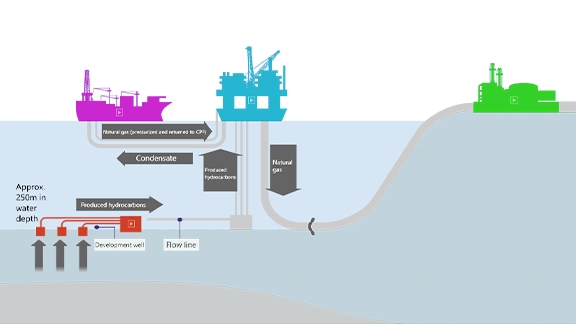

The extracted oil and natural gas are refined and processed for use as products.

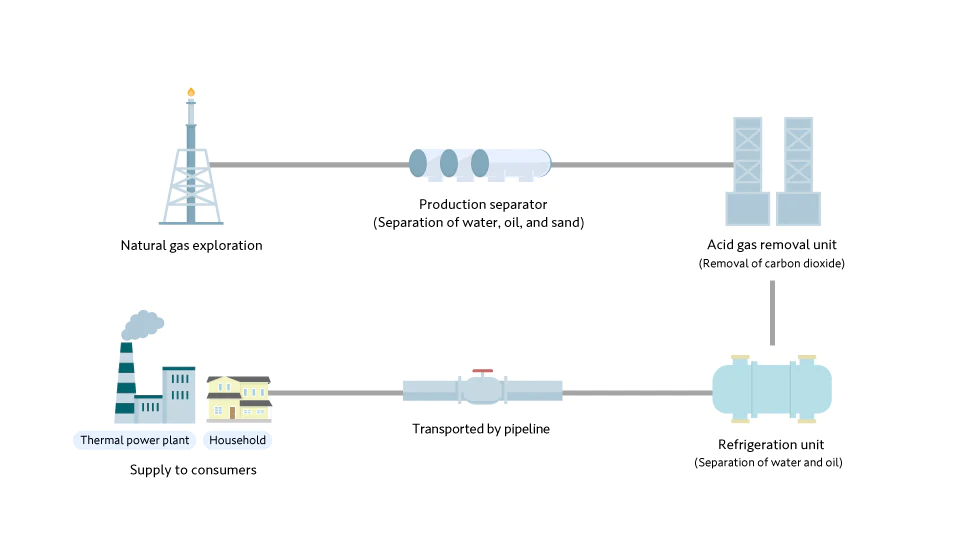

Natural Gas

Separate oil and process impurities

The extracted natural gas contains oil and impurities (such as carbon dioxide, water, and mercury). Since it cannot be used as a product as it is, it is sent to a processing plant, where the oil is separated by a separator and the impurities are treated with carbon dioxide removal equipment, refrigeration equipment, and adsorbents, and then dispatched as natural gas that everyone can use.

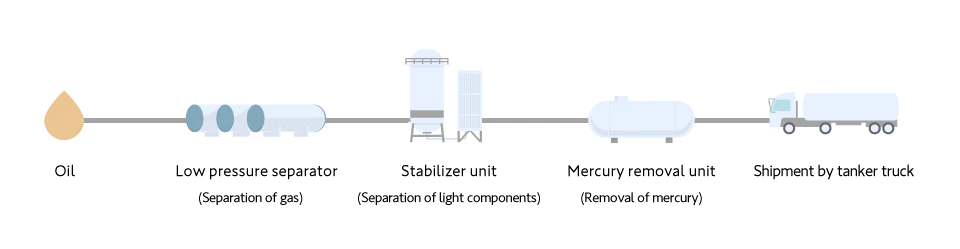

Oil & Condensate

Separate gas and remove impurities.

The oil separated from the natural gas may contain gases and mercury. Therefore, the gas is separated using a distillation apparatus, and mercury is removed using adsorbents. The processed oil fraction is called condensate, which is shipped to oil refineries and refined into oil products such as LPG, naphtha (a raw material for petrochemical products), gasoline, kerosene, light oil and heavy oil.

The oil and natural gas that have undergone such processing are used widely at the consumer end.

Transportation

The refined and processed oil and natural gas are transported via pipelines, tankers or trucks.

1 Delivering from overseas to Japan [LNG transport]

Since Japan's domestic natural gas production accounts for less than 4% of domestic consumption, the remaining approximate 96% is imported as LNG from places like Indonesia, Australia and the Middle East. INPEX, aiming to secure a sufficient natural gas supply capacity in the medium to long term, started operating the Ichthys LNG Project in 2018, which has the capacity to produce 9.3 million tons of LNG per year, with around 70% being supplied to Japan. In addition, an LNG receiving base has been built in Joetsu City, Niigata Prefecture (Naoetsu Port), and it has been in operation since 2013.

2 Supplying domestic gas [Pipeline]

The LNG that arrives from overseas is re-gasified at a receiving base, mixed with domestic gas, and sent to pipelines. The natural gas transported across rivers and mountains is widely used by city gas operators and manufacturing plants, supporting our daily lives.

3 Transporting oil products [Sea and land transport]

When transporting oil products, specialized tankers are used at sea, and pipelines, trucks or freight trains on land. By ensuring safe delivery to necessary locations, it serves a variety of uses, such as fuel for manufacturing plants and automobiles.

4 Familiar oil products [Supply to various uses]

Oil products are used for a variety of purposes. They are used as a heat source in factories and homes, and as a power source in automobiles, ships and aircraft. Furthermore, they are used as raw materials for products like detergents, plastic products and synthetic fibers.